Not all options are created equally regarding gold plating. The electronics industry relies heavily upon gold plating services, and different applications require specific characteristics. In this blog post, we will highlight the differences between hard gold and soft gold plating, outlining their distinct properties and suitable applications within the electronics sector.

Gold in Printed Circuit Board (PCB) Technologies

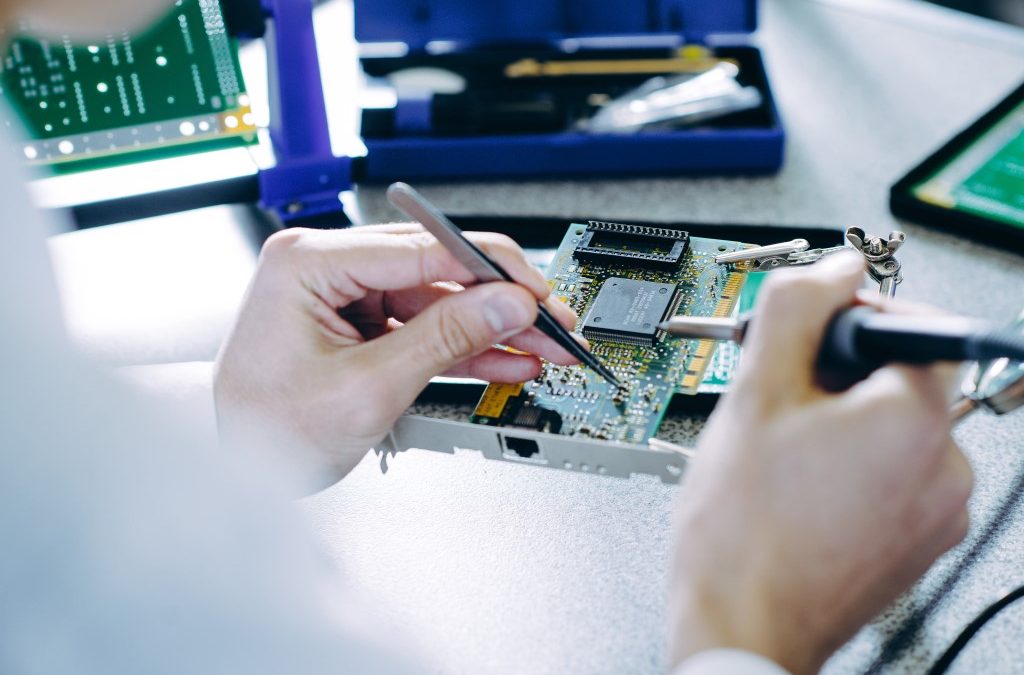

Printed circuit board technologies extensively use gold due to their excellent properties, including good electrical conductivity, tarnish resistance, solderability after storage, and exceptional etch resistance. Electrolytic Ni/Au involves a layer of gold plating over a base of electroplated nickel, offering a versatile option for various applications. Within this context, both hard and soft gold plating can be utilized, each offering unique advantages based on specific requirements and use cases.

Hard Gold Plating

Hard gold plating is a gold alloy that incorporates cobalt and/or nickel complexes. This type of plating is typically employed for applications that demand minimum contact resistance and connector tabs. Its superior hardness and durability make it well-suited for scenarios where components are subjected to frequent repetitive insertions. However, due to its inherent characteristics, hard gold plating is not suitable for wire bonding applications.

In terms of standards compliance, hard gold plating adheres to MIL-DTL-45204 Type I and II, Grade C, as well as ASTM B 488, Types I and II, Code C. The hardness range of hard gold plating typically falls between 130-200 Knoop, ensuring robust performance in demanding environments. Additionally, the gold purity in hard gold plating is a minimum of 99.70%, meeting stringent quality requirements for electronic applications.

Soft Gold Plating

Conversely, soft gold plating is tailored for specific applications that require wire bonding, high solderability, and weldability. Boards designed for applications that involve wire bonding benefit from the characteristics of soft gold plating, ensuring reliable electrical connections and seamless integration within electronic assemblies. The softness of this plating option contributes to its compatibility with wire bonding processes, enabling efficient and secure bonding.

In terms of standards compliance, soft gold plating meets the requirements of MIL-DTL-45204, Type III, Grade A, and ASTM B 488, Types III, Code A. With a maximum hardness of 90 Knoop, soft gold plating offers the necessary characteristics for applications that demand flexibility and adaptability. Moreover, the gold purity in soft gold plating is a minimum of 99.90%, underscoring its high-quality composition and suitability for critical electronic components.

Superior Processing’s Contribution

As a leading provider of gold plating services, Superior Processing offers a comprehensive range of solutions tailored to meet the electronics industry’s diverse needs. With a deep understanding of the distinct properties of hard and soft gold plating, Superior Processing is dedicated to delivering high-quality plating services that align with specific application requirements.

By leveraging advanced techniques and industry expertise, Superior Processing ensures that customers receive gold plating solutions that optimize the reliability and performance of their electronic components.

Conclusion

In conclusion, the choice between hard gold and soft gold plating hinges on the specific requirements of the intended application within the electronics sector. Understanding the unique properties and standards compliance of each type of gold plating is essential in making informed decisions that drive the performance and longevity of electronic components.

Superior Processing’s commitment to excellence and precision in gold plating services allows customers to confidently integrate the ideal gold plating solutions into their electronic designs, ensuring superior performance and reliability.