ENEPIG

(Electroless Nickel, Electroless Palladium, Immersion Gold)

ENEPIG (Electroless Nickel, Electroless Palladium, Immersion Gold)

ENEPIG is a coating often referred to as the “universal finish”. That is because it can be soldered or wire bonded with the same coating. ENEPIG is the ENIG process with the added layer of palladium. The palladium helps protect the nickel layer from corrosion. This is one of the distinct advantages of ENEPIG over the ENIG surface finish. The immersion gold layer on top the palladium is to protect and preserving the palladium underneath.

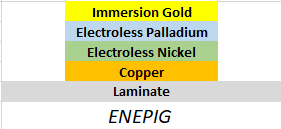

The ENEPIG surface finish is composed of four metal layers: Copper, Nickel, Palladium & Gold.

Diagram illustrating the layers of ENEPIG.

Superior Processing’s ENEPIG meets the requirements of IPC 4556. The Palladium layer is used for wire bonding and the nickel is used during the assembly soldering operations.

The nickel layer in the ENIG also complies with:

- ASTM B733

- SAE AMS2404

- MIL-C-26074

IPC-4556 specifies the thickness of each layer being per the table below but for some applications different thickness are specified by our customer.

| ENEPIG per IPC-4556 |

micro inches (µin) | micrometers (µm) | ||

| Minimum | Maximum | Minimum | Maximum | |

| Nickel (Ni) | 118.1 | 236.2 | 3.000 | 6.000 |

| Palladium (Pd) | 2 | 12 | 0.050 | 0.300 |

| Gold (Au) | 1.2 | 2.8 | 0.030 | 0.070 |

| Thickness based on measuring on a 0.060″ x 0.060″ pad. | ||||

READY TO START A PROJECT?

SUPERIOR PROCESSING

1115 Las Brisas Pl, Placentia, CA 92870

Office Hours: Monday-Friday, 8AM-5PM

(714) 524-8525