Today, in the electronics industry, reliable, cost-effective and environmentally friendly plating options are needed. Immersion tin, a lead-free and RoHS-compliant surface finish, has become one solution that has gained a lot of traction. Immersion tin applications are the specialty of Superior Processing, providing an efficient and flat surface for precise, intricate electronic assemblies.

In this blog, the properties, advantages and ideal applications of immersion tin are explored, and it is shown that immersion tin is a viable alternative to lead-based finishes in electronics.

Understanding Immersion Tin Plating

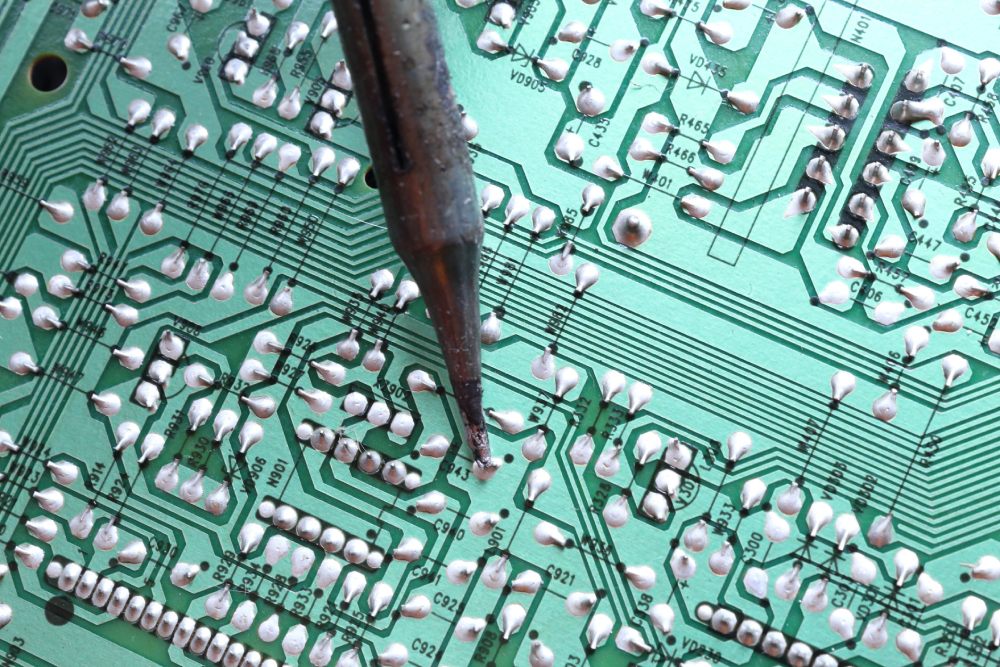

Immersion tin plating involves depositing a thin, uniform layer of pure tin onto the copper surface of a printed circuit board (PCB). This process results in a smooth and extremely flat finish that is well-suited to fine-pitch components and small geometries. Superior Processing’s immersion tin meets rigorous industry standards, including IPC-4554 and MIL-T-81955, which define thickness requirements to ensure product consistency and reliability.

In immersion tin plating, the tin layer is a “sacrificial coating” that protects the copper beneath from oxidation and other environmental effects. This finish directly bonds to the copper, eliminating the need for additional layers and streamlining the manufacturing process to a cost-effective solution. Immersion tin is a high flatness, reliable and durable lead-free plating option for manufacturers seeking a lead-free plating option without sacrificing quality.

Key Benefits of Immersion Tin

The advantages of the immersion tin process make it a desirable process for electronics applications.

Lead-Free and RoHS Compliance

Immersion tin is a lead-free finish, and is environmentally friendly and RoHS compliant. For electronics manufacturers looking for eco-friendly solutions that also meet international regulations to gain broader market access and a safer product profile, this compliance is crucial.

Exceptional Flatness

The flatness of immersion tin is one of its standout properties. This flat surface is ideal for fine-pitch components, enabling precise connections and effective solderability. It makes immersion tin an excellent option for PCBs that require accuracy in small geometries and surface-mounted components, reducing the risk of bridging and other assembly issues.

Cost-Effective Production

Immersion tin has less layers than some other finishes, so it simplifies the process and can reduce costs. The streamlined approach of immersion tin makes it a popular choice for manufacturers who want to balance quality with budget.

Compatible with Fine Geometries

Immersion tin offers high flatness and smooth surface, which is compatible with intricate and compact designs. This plating provides consistent, reliable performance for applications requiring high-density PCBs or complex circuitry.

Meets Industry Standards

Immersion tin process from Superior Processing meets IPC-4554 and MIL-T-81955 requirements for specific thicknesses for different applications. Because we are committed to quality, each layer of tin meets or exceeds these standards, assuring reliable performance in all electronics applications.

Applications of Immersion Tin in Electronics

Due to its unique properties, immersion tin is well-suited for a variety of applications within the electronics industry:

- Printed Circuit Boards (PCBs): As flatness is widely used in PCB manufacturing, immersion tin is used widely in fine pitch and surface mount technologies.

- Consumer Electronics: Immersion tin’s smooth finish is ideal for compact designs and devices with fine circuitry, like smartphones and tablets.

- Automotive Electronics: As demand for electronics in vehicles increases, immersion tin provides durability and reliability for automotive PCBs enabling a variety of safety and infotainment functions.

- Medical Devices: For medical applications where high reliability and precision are required, immersion tin is an excellent choice for use in complex medical devices, and is known to perform reliably.

- Aerospace Applications: Immersion tin is suitable for aerospace electronics that must withstand extreme conditions because of its stability and compliance with industry standards.

Why Choose Superior Processing for Immersion Tin Solutions?

Superior Processing stands out in the industry with unmatched expertise in immersion tin plating. Our state-of-the-art facilities and skilled professionals ensure that every immersion tin coating we provide meets stringent quality requirements, delivering precision and reliability in every product. By complying with IPC-4554 and MIL-T-81955 standards, we offer immersion tin coatings that meet industry demands while also catering to custom specifications for unique applications.

For electronics manufacturers, choosing the right surface finish is crucial for product quality and regulatory compliance. Immersion tin offers an effective balance of flatness, durability, and cost savings, making it a preferred choice for manufacturers focused on lead-free and eco-friendly solutions. Reach out to Superior Processing today to learn how our immersion tin solutions can support your project’s unique requirements.