Immersion Tin

(White Solderable Tin)

Immersion Tin (White Solderable Tin)

IPC Code: ISn

Immersion tin is a lead-free surface finish compliant with the Restriction of Hazardous Substances (RoHS) directive. It is particularly suitable for PCBs with flat surface requirements and fine-pitch components. This type of finish involves depositing a thin layer of pure tin onto the Copper layer of the PCB, resulting in a very flat and smooth surface.

Immersion tin is an excellent alternative to lead-based surface finishes and is widely used due to its high flatness, making it an ideal choice for small geometries and fine-pitch surface mount components.

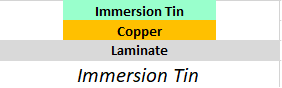

Diagram illustrating the layers of Immersion Tin.

Our Immersion Tin meets the requirements of IPC-4554 and MIL-T-81955.

IPC-4554 specifies the thickness of each layer per the table below, but for some applications, different thicknesses are specified by our customer.

| Immersion Tin per IPC-4554 | micro inches (µin) | micrometers (µm) |

| Minimum | Minimum | |

| Tin (Sn) | 40 | 1.016 |

| Thickness based on measuring on a 0.060″ x 0.060″ pad. | ||

Overview

At Superior Processing, we take great pride in our unparalleled immersion tin surface finish field expertise. With an unwavering commitment to excellence and state-of-the-art technology, we provide our clients with superior quality and precision at every stage of the immersion tin process.

Our relentless pursuit of innovation and unwavering focus on customer satisfaction set us apart as a trusted and dependable partner for all your electronic component finishing needs.

Immersion Tin is a lead-free surface finish that is fully compliant with RoHS and Reach standards. It offers numerous advantages for electronic assembly, making it a preferred choice for manufacturers looking to save costs.

The exceptional flatness and fine pitches of immersion tin make it highly compatible with fine geometries and surface mount components. This versatility makes it a reliable option for diverse electronic applications, ensuring efficient and dependable performance in diverse electronic systems.

Meeting Industry Standards with Immersion Tin Application

Directly applied onto copper, Immersion Tin complies with IPC-4554 and MIL-T-81955 specifications. IPC-4554 delineates the layer thicknesses according to a designated table, although certain customer applications may necessitate varying thicknesses for specific requirements.

This ensures that our Immersion Tin aligns with industry standards and customer-specific needs, guaranteeing the quality and performance of the finished product.

Precision and Quality Assurance in Immersion Tin Coating

The utilization of Immersion Tin not only ensures compliance with environmental regulations but also provides a reliable surface finish for intricate electronic components. By meeting the standards set by IPC-4554 and MIL-T-81955, our Immersion Tin process guarantees consistency and precision in layer thickness, catering to a diverse range of customer applications.

This attention to detail and adherence to industry specifications underscores our commitment to delivering high-quality and tailored solutions in the realm of surface finishes for electronic assemblies.

Experience Unmatched Expertise and Precision with Superior

Processing’s Immersion Tin Surface Finish Solutions

At Superior Processing, we are confident that we can provide you with exceptional solutions that meet your unique requirements. Our expertise in immersion tin surface finish and our commitment to quality and precision make us the perfect partner.

To learn more about our services, please contact us today. We look forward to the opportunity to work with you.

READY TO START A PROJECT?

SUPERIOR PROCESSING

1115 Las Brisas Pl, Placentia, CA 92870

Office Hours: Monday-Friday, 8AM-5PM

(714) 524-8525