Electrolytic Nickel, Gold

(Hard & Soft Gold)

Electrolytic Nickel, Gold (Hard & Soft Gold), or Nickel / Gold

IPC Codes: G, GS, GWB-1, GWB-2, N, NB (Depending on application).

Depending on applications, printed circuit board technologies use gold extensively. Gold has good electrical conductivity, tarnish resistance, solderability after storage, and being excellent etch resist. Electrolytic Ni/Au has a layer of gold plating over a base of electroplated nickel. Hard or Soft Gold can be used with each option.

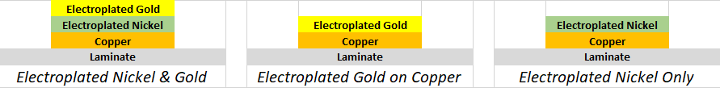

Diagram illustrating the different applications of Electroplating.

Hard gold is a gold alloy with complexes of cobalt and/or nickel. is typically used for minimum contact resistance, connector tabs. Hard gold is not suitable for wire bonding.

- Complies with

- MIL-DTL-45204 Type I and II, Grade C

- ASTM B 488, Types I and II, Code C

- Hardness range of 130-200 Knoop.

- The Gold purity is a minimum of 99.70%.

Soft gold finish is typically used for boards designed mostly for applications that require wire bonding, high solderability and weldability.

- Complies with

- MIL-DTL-45204, Type III, Grade A

- ASTM B 488, Types III, Code A

- Hardness maximum of 90 Knoop.

- The Gold purity is a minimum of 99.90%.

Nickel is a low stress, semi-bright, ductile deposit.

- Complies with

- SAE AMS-QQ-N-290 Class 1 and 2

- SAE AMS2423

- SAE AMS2403

- ASTM B689-97

- SAE AMS2424 (Special Request Required)

IPC-6011 gives a guideline for the thickness requirements for each layer being per the table below but for some applications different thickness are specified by our customer.

| IPC Thickness Requirements per IPC-6011 | ||

| Code | Finish | Thickness |

| G | Gold for edge printed board connectors and areas not to be soldered | Class 1 & 2 31.5 µin minimum Class 3 49.21 µin minimum |

| GS | Gold Electroplate on areas to be soldered | 17.72 µin maximum |

| GWB-1 | Gold Electroplate for areas to be wire bonded (ultrasonic) | 1.97 µin minimum |

| Electrolytic nickel under gold for areas to be wire bonded (ultrasonic) | 118 µin minimum | |

| GWB-2 | Gold Electroplate for areas to be wire bonded (thermosonic) | Class 1 & 2 11.8 µin minimum Class 3 31.5 µin minimum |

| Electrolytic nickel under gold for areas to be wire bonded (thermosonic) | 118 µin minimum | |

| N | Nickel – Electroplate for edge printed board connectors | Class 1 78.7 µin minimum Class 2 & 3 98.4 µin minimum |

| NB | Nickel – Electroplate as a barrier | 51.2 µin minimum |

READY TO START A PROJECT?

SUPERIOR PROCESSING

1115 Las Brisas Pl, Placentia, CA 92870

Office Hours: Monday-Friday, 8AM-5PM

(714) 524-8525