ENEPIG

(Electroless Nickel, Electroless Palladium, Immersion Gold)

ENEPIG (Electroless Nickel, Electroless Palladium, Immersion Gold)

ENEPIG is a coating often referred to as the “universal finish.” It can be soldered or wire bonded with the same coating. ENEPIG is the ENIG process with an added palladium layer, which helps protect the nickel layer from corrosion.

One of the distinct advantages of this coating over the ENIG process is that it comprises an added palladium layer, safeguarding the nickel layer from corrosion. The immersion gold layer on top of the palladium provides additional protection and preserves the palladium underneath.

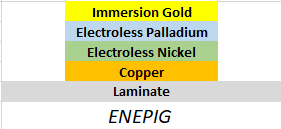

The ENEPIG surface finish comprises four distinct metal layers that work together to provide superior protection and preservation for the underlying circuitry. These layers include:

- Copper

- Nickel

- Palladium

- Gold

Combining these four layers, ENEPIG offers a high-performance surface finish that can be easily soldered or wire-bonded. This makes ENEPIG an ideal choice for various applications where reliability and performance are paramount.

Diagram illustrating the layers of ENEPIG.

Superior Processing’s ENEPIG meets the requirements of IPC 4556. The Palladium layer is used for wire bonding, and the nickel is used during the assembly soldering operations.

The nickel layer in the ENIG also complies with:

- ASTM B733

- SAE AMS2404

- MIL-C-26074

IPC-4556 specifies the thickness of each layer per the table below, but our clients select different thicknesses for some applications.

| ENEPIG per IPC-4556 | micro inches (µin) | micrometers (µm) | ||

| Minimum | Maximum | Minimum | Maximum | |

| Nickel (Ni) | 118.1 | 236.2 | 3.000 | 6.000 |

| Palladium (Pd) | 2 | 12 | 0.050 | 0.300 |

| Gold (Au) | 1.2 | 2.8 | 0.030 | 0.070 |

| Thickness based on measuring on a 0.060″ x 0.060″ pad. | ||||

Overview

At Superior Processing, we take pride in our reputation as a distinguished entity in the field of coating solutions. Our expertise lies in providing exceptional ENEPIG coatings, which are widely recognized as the “universal finish” due to their remarkable versatility in soldering and wire bonding applications.

ENEPIG is an advanced version of the ENIG process that includes a palladium layer. This layer provides superior corrosion protection for the underlying nickel layer, setting it apart from traditional ENIG surface finishes. Furthermore, the additional immersion gold layer enhances the protective properties, ensuring the coating’s durability and reliability.

Understanding ENEPIG Coating Composition

The composition of the ENEPIG surface finish comprises four essential metal layers:

- Copper

- Nickel

- Palladium

- Gold

Each layer has a vital role in ensuring the functionality and performance of the coating. The palladium layer is designed to facilitate wire bonding applications, while the nickel layer is essential for assembly soldering operations.

Compliance with Industry Standards

Our ENEPIG coatings adhere to the stringent requirements outlined in IPC-4556, ensuring the coatings meet industry standards for quality and performance. The utilization of palladium for wire bonding and nickel for soldering aligns with the specifications set forth by IPC-4556, highlighting our commitment to delivering coatings that meet the highest industry benchmarks.

Nickel Layer Specifications and Standards

In addition to the palladium layer, the nickel layer in the ENIG coating we offer complies with a range of industry standards, including the following:

- ASTM B733

- SAE AMS2404

- MIL-C-26074

These standards validate the quality and reliability of the nickel layer, guaranteeing it meets the rigorous requirements of various applications and industries.

Thickness Specifications and Customization

IPC-4556 stipulates specific thickness requirements for each layer of the ENEPIG coating, as detailed in the provided table. However, we acknowledge that particular applications may require customized thickness specifications to align with our client’s needs.

Our flexibility in accommodating varying thickness requirements accentuates our commitment to delivering tailored solutions that cater to each project’s specific demands.

Ensuring Quality and Precision in ENEPIG Coatings

Our dedication to excellence shines through in our attention to detail when creating ENEPIG coatings. Our focus on meeting and surpassing industry benchmarks, providing customization choices, and implementing strict quality checks guarantees our coatings offer outstanding performance and dependability. We craft precision instruments tailored to meet your specific needs.

We invite you to experience the unmatched quality and reliability of our ENEPIG coatings. Contact us today to learn more about our customization options and to discuss how we can tailor our precision instruments to fulfill your unique requirements. Let us be your trusted partner in achieving your goals.

READY TO START A PROJECT?

SUPERIOR PROCESSING

1115 Las Brisas Pl, Placentia, CA 92870

Office Hours: Monday-Friday, 8AM-5PM

(714) 524-8525